Adhesive wheel weights – what are the differences?

Ever counted how many of your customers have ALU rims in their cars? Well, for sure that’s a lot. And for you this means nothing else but buying a larger quantity of adhesive wheel weights. A larger stock would not hurt, that’s for sure. However, there is another thing – what type of wheel weights should you choose? There’s a range of categories. We’d try to suggest you the best choice.

Adhesive wheel weights – what surface?

When looking at types of adhesive wheel weights available on the market, you can see that they differ by the type of surface. Here’s a short list of surface types you can choose from:

- polymer

- coated

- zinc-plated

What are the differences? Let’s think about it!

Polymer surfaces

These are usually used for adhesive wheel weights made of lead. Did you know there are adhesives based on this material? They are mainly used for motorcycle wheels. And when you compare them with adhesive wheel weights for cars, they are a bit thicker. It is important to know that weights made of lead are not that prone to corrosion like those made of other materials. And one more thing – those adhesive wheel weights cannot be used on rims of cars driving through numerous EU countries.

Adhesive wheel weights – painted surface

This is just a paint of a certain color. We got them in Edgy shape, for instance – they are in black. Thanks to that, they perfectly fit darker rims.

Obviously, you can find adhesive wheel weights in other colors, too. However, the black ones are the most universal choice – they fit darker rims. Thanks to their color, you can easily hide them behind the wheel spokes.

Adhesive wheel weights – zinc-plated

The zinc-plated weights are galvanized. This means, they are less prone to corrosion – which is an obvious thing if the car is driving through salty roads.

How to choose adhesive wheel weights?

When on the lookout for the adhesive weights, consider the following:

- design

- surface protection

- ease of mounting on the rim.

How to choose these?

Design

It’s been a long time since most cars had small tyres. By default, most contemporary cars have rims sized 17 or even 18”. And roads are getting better all around Europe, so more and more car owners settle for ALU rims. So, here choosing the right wheel weights comes into play.

The larger the rim, the higher the risk that the weight looks like an element that was stuck there as if by accident. It should rather fit the overall rim design – so, it might be a good idea to sort mode silver or black wheel weights.

Before you settle for a certain type of adhesive wheel weights, make sure to check how their surface is protected. Don’t be afraid to inquire the seller about it. Usually, adhesive wheel weights are protected using an epoxide surface. Galvanization is another popular method of protecting their surface.

Why is that so important?

If the weights are protected that way, they are less prone to corrosion. It also lets them keep their looks for longer.

So you don’t have to be afraid about a client coming up and complaining about ugly looks of their rim – be it dirt, be it corrosion. Do not make the clients stay away from your tyre service!

Ease of mounting

Ever counted how many cars you work at daily? be it 30. Be it 40. It all takes time. Loads of time. You have to take off every wheel, then balance it, then mount it again. It is time-consuming, isn’t it?

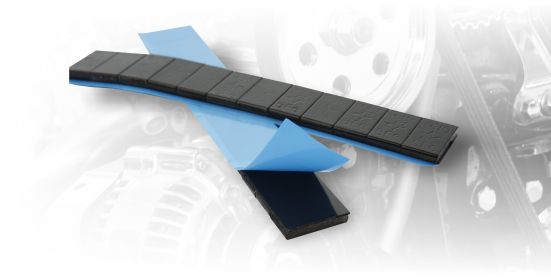

Are wheel weights of any importance here? Yes. Quite a huge one. It is important that the tape can easily be taken off the surface. In weights of good quality, the tape sticks out of the edges. You should be able to grab it by hand and take off. Saving a few seconds may not seem like a lot but if you deal with many cars during the day, it makes your work faster.